Finishing Dynamics®

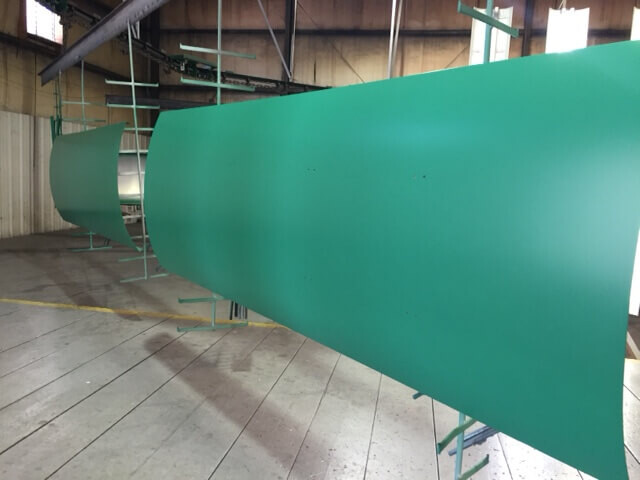

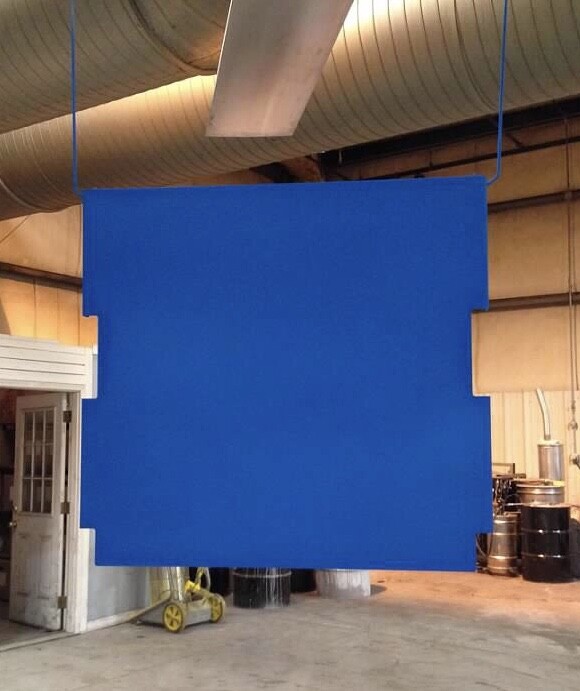

Finishing Dynamics® consistently has a competitive edge over other facilities. Their paint line efficiency, ability to process up to 10,000 square feet a day and quick color changes save customers time and money. With over two decades of experience in the industry, Finishing Dynamics® utilizes cutting edge technology and boasts a processing window of 4’ wide x 5.5’ high x 38’ long. Customers are encouraged to visit the 75,000+ square foot facility. From rain screens, wall panels, brake metal and sunshades to brackets and mullions, let their expert team help with your next project!

For architectural engineered metal products, explore their in-house sister company, American Metalcraft® – also WBE certified. Since 1986, American Metalcraft has continued to be a proven leader in the industry. They offer design assist, engineering, fabrication and

finishing all under one roof. Product line includes solid plate aluminum rain screens, perforated panels, ornamental and brake metal, custom sunshades, column covers, exterior elements and more. As a trusted resource for the A/E/C community, put their wealth of experience to work for you.

As an industry leader in PVDF (polyvinylidene fluoride) using Kynar® 500 PVDF resin for commercial metal products, they are an approved applicator for Sherwin-Williams® and PPG Industries, Inc.

Metal is chemically cleaned and treated using our five stage pre-treatment system. All paint is

manually applied using electrostatic paint guns and is cured in their industrial bake oven. The manual process provides more complete coverage than automated spray systems. Each piece is checked and tested rigorously by their quality department.

They meet and exceed all AAMA 2605 testing procedures.